APIs for Integration; Not All APIs Are The Same

Earlier this year MOVUS Founder and CEO Brad Parsons published an interesting post about the Six Platform Must Haves customers should consider when evaluating Industrial IoT solutions.

Posts by:

Earlier this year MOVUS Founder and CEO Brad Parsons published an interesting post about the Six Platform Must Haves customers should consider when evaluating Industrial IoT solutions.

In manufacturing, unplanned downtime is a profit and reputation killer, and also significantly impacts a manufacturers ability to hit OEE targets (as MOVUS discussed with OEE expert Clive Moore earlier this year). This new case study from Australian manufacturer Matrix Polymers highlights the value of continuous condition monitoring.

MOVUS is pleased to advise that FitMachine EX is now certified for use in Queensland underground coal mines! This is an important extension of our existing intrinsically safe certification. Details of the new certification can be found here.

MOVUS received great feedback from one of our global mining customers last week as FitMachine again demonstrated its value as the world’s leading continuous condition monitoring solution. This post is a summary of the conversation between this customer and our global engineering partner ALS (who manage this relationship).

In late May the MOVUS engineering team released a major upgrade to our MachineCloud platform. There were a lot of behind-the-scenes changes that set our platform up for the future, and a range of customer facing changes like improved graphing, data loading, and even simpler navigation (less clicks). One small addition that may have gone unnoticed is really important for our customers…

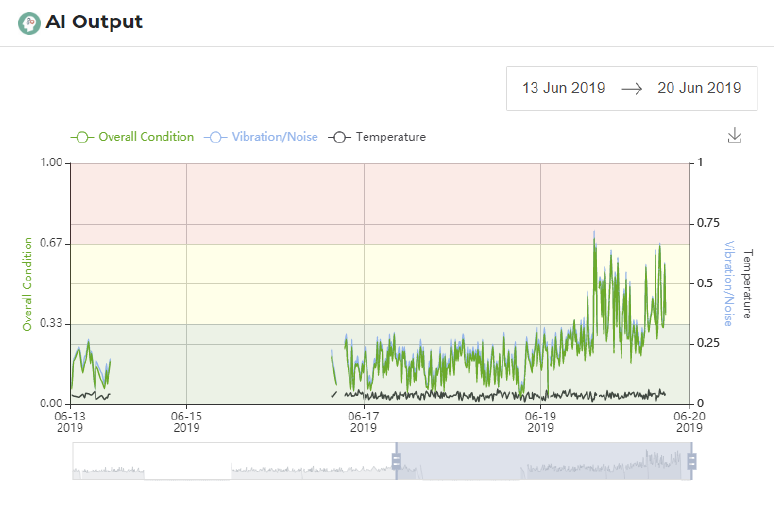

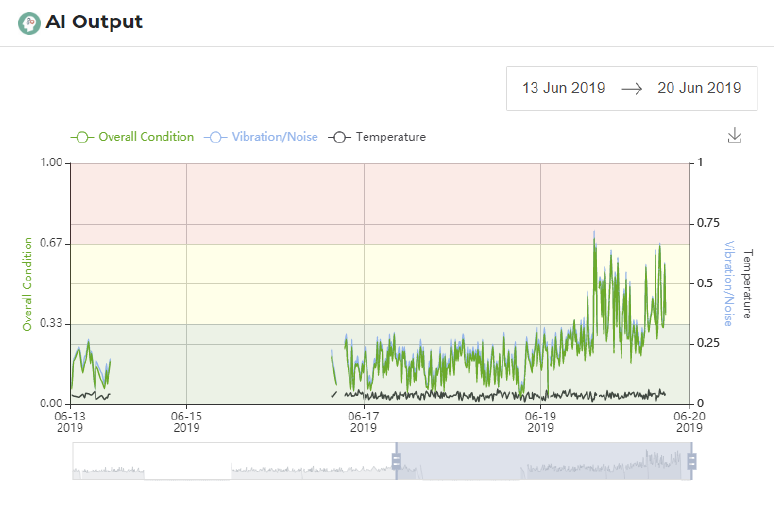

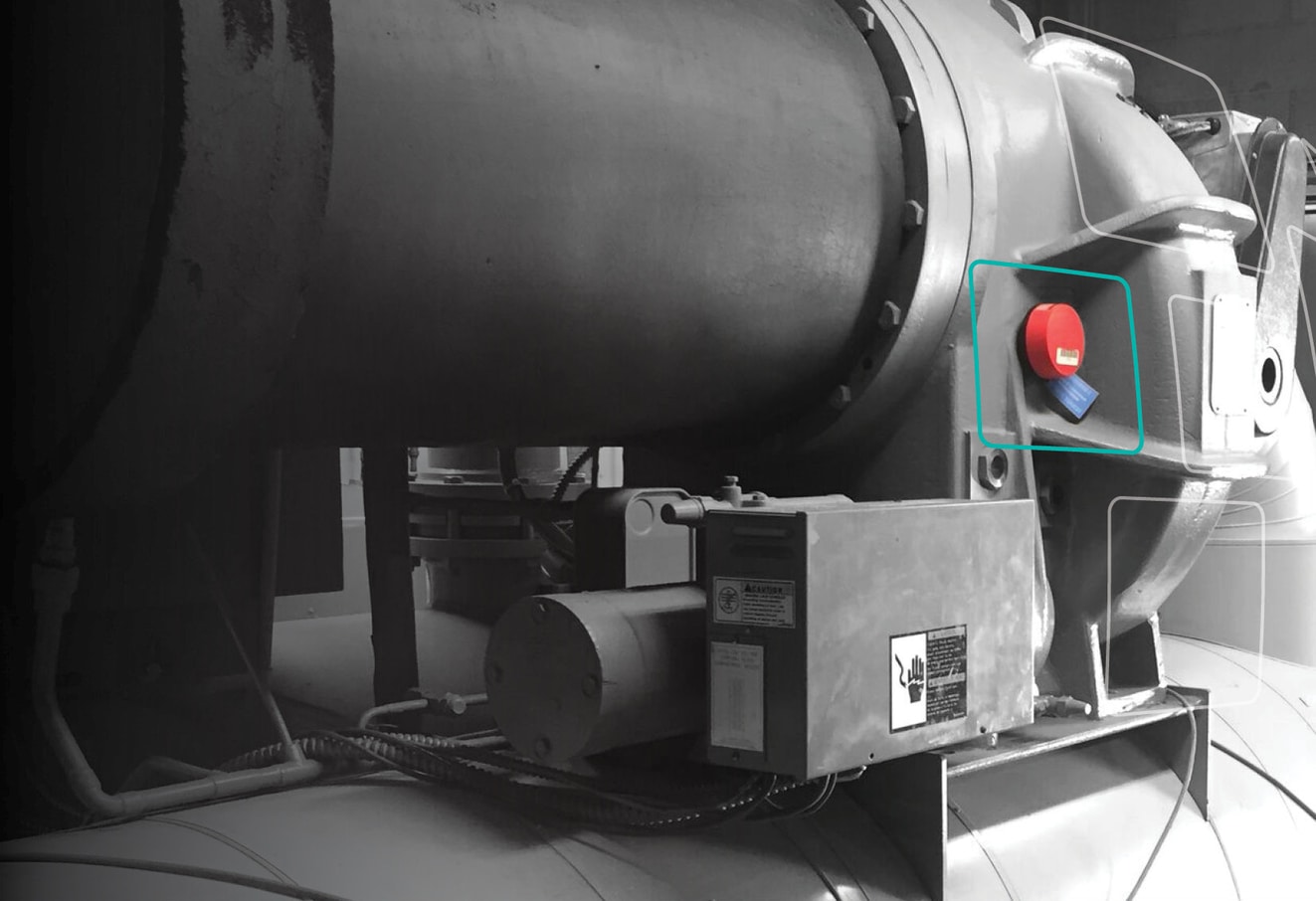

One of the key benefits of continuous condition monitoring is that it acts as an early warning system – giving maintenance teams advance notice of subtle changes that, if left unattended could degrade into more permanent damage or a failure. In late June, one of our chemical and fertiliser manufacturing customers provided feedback to us about an alert they received.

MOVUS received great feedback from one of our global mining customers last week as FitMachine again demonstrated its value as the world’s leading continuous condition monitoring solution. This post is a summary of the conversation between this customer and our global engineering partner ALS (who manage this relationship).

The University of Queensland is one of Australia’s largest and most prestigious Universities with facilities and operations spread around Queensland. Whilst UQ is considered an Ivy League University, it also has a reputation for being an early adopter of innovative technology – so its no wonder UQ was one of MOVUS’s first customers for its world leading continuous condition monitoring solution – FitMachine.

Building on an existing collaboration partnership, MOVUS is pleased to announce that it has signed a reseller agreement with ALS Global to introduce our world leading continuous condition monitoring solution – FitMachine – to industrial markets in both North and South America.

As many of us know, manufacturing in Australia continues to be a vital contributor to our economy, the sector continues to grow and turn out world leading products. But there is continued pressure on the sector – Are we cost competitive? Is our labour cost too high? Can we innovate? How do we grow when we don’t have the scale of overseas markets like Asia, Europe, or the Americas?