4 Ways Condition Monitoring Improves Planned Performance

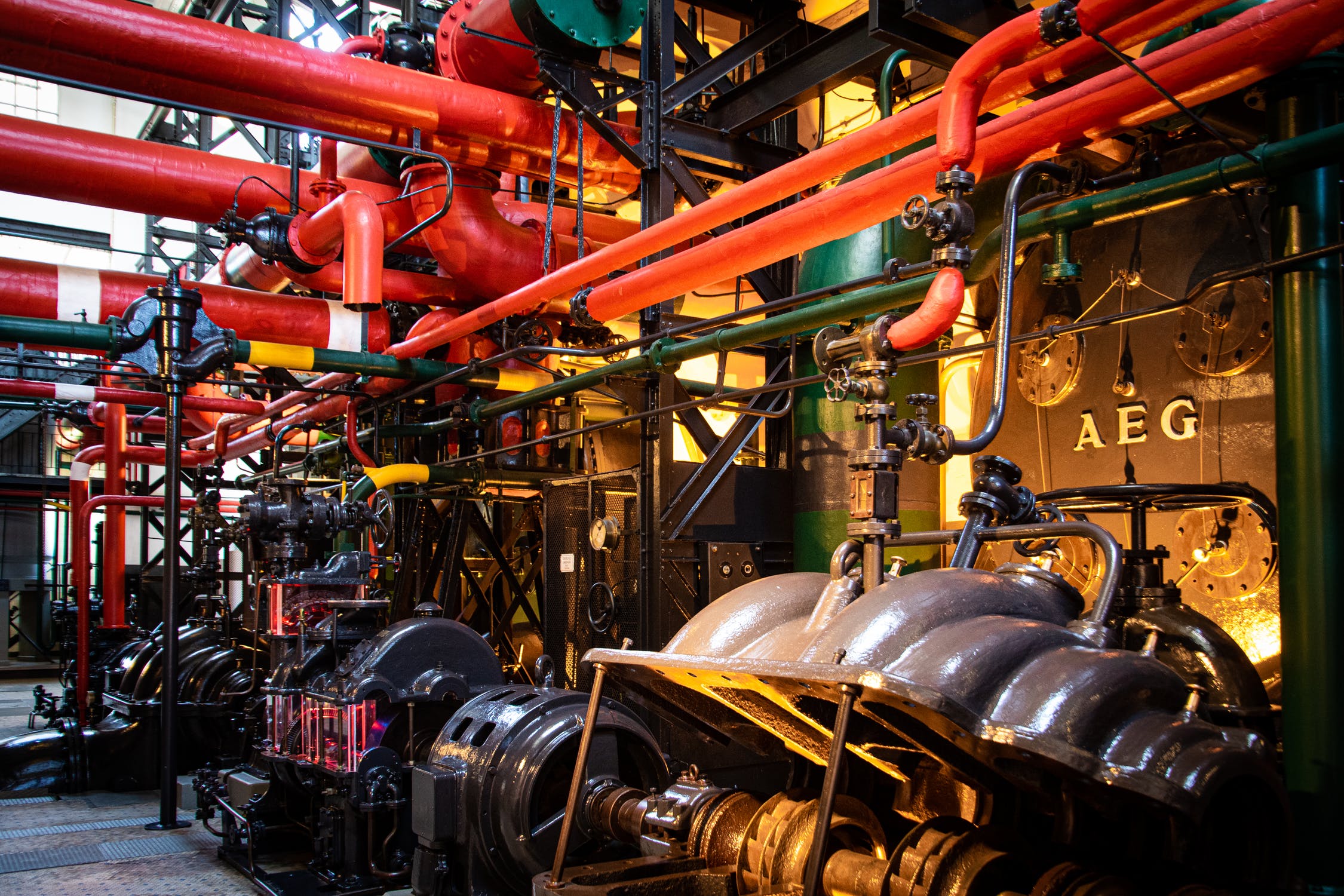

Good maintenance processes and maintenance tech (like condition monitoring) are the key to operational efficiency.

It may be a cliche to say that the world moves faster today than it did in the past. However, that doesn’t make it any less true, particularly for manufacturers. Waste of any kind—in time, money, or resources—can end up hitting your bottom line hard.

Staying ahead of the game (and the competition) requires careful planning, a laser-like focus on efficiency, and a commitment to ongoing improvement.

The good news is that the same technology that has created the fast pace of change is the same technology that offers us the ability to do better than we have ever done before.

Some of the most powerful tools available to operations and maintenance planners, managers in manufacturing are condition monitoring and predictive maintenance.

And who is your most valuable partner in taking these simple but crucial steps to improve your planned performance? Equipment monitoring technology.

Before we dive into how operations and maintenance teams stand to benefit from this technology, let’s take a quick look at what predictive monitoring and predictive maintenance are and how they work.

What Are Condition Monitoring and Predictive Maintenance?

The best condition monitoring tools use artificial intelligence to do what is generally beyond the scope of human capability: observe and monitor data points that, over time, establish equipment’s normal operating behaviour and sound the alarm when abnormal behaviour is detected.

In short, condition monitoring detects problems at the most important time: before they happen.

Predictive maintenance harnesses data and artificial intelligence to identify the best time to perform maintenance, rather than simply doing it according to an inflexible schedule. This frees up maintenance teams to perform other work and not devote time to unnecessary maintenance simply because the schedule says so.

See a condition monitoring platform in action – https://learn.movus.com.au/trial

How Can This Help Me?

Let us count the ways. The benefits of condition monitoring and predictive maintenance include:

- Preventing the wasting of resources

- Avoiding sudden breakdowns and unplanned downtime

- Increasing efficiency and overall equipment effectiveness (OEE)

- Supporting informed decision-making

In other words, and to draw on another relevant cliche, an ounce of prevention is worth a pound of cure.

That’s why equipment monitoring technologies, such as FitMachine, are such powerful allies for operations and maintenance managers in the fight to stay ahead of the competition.

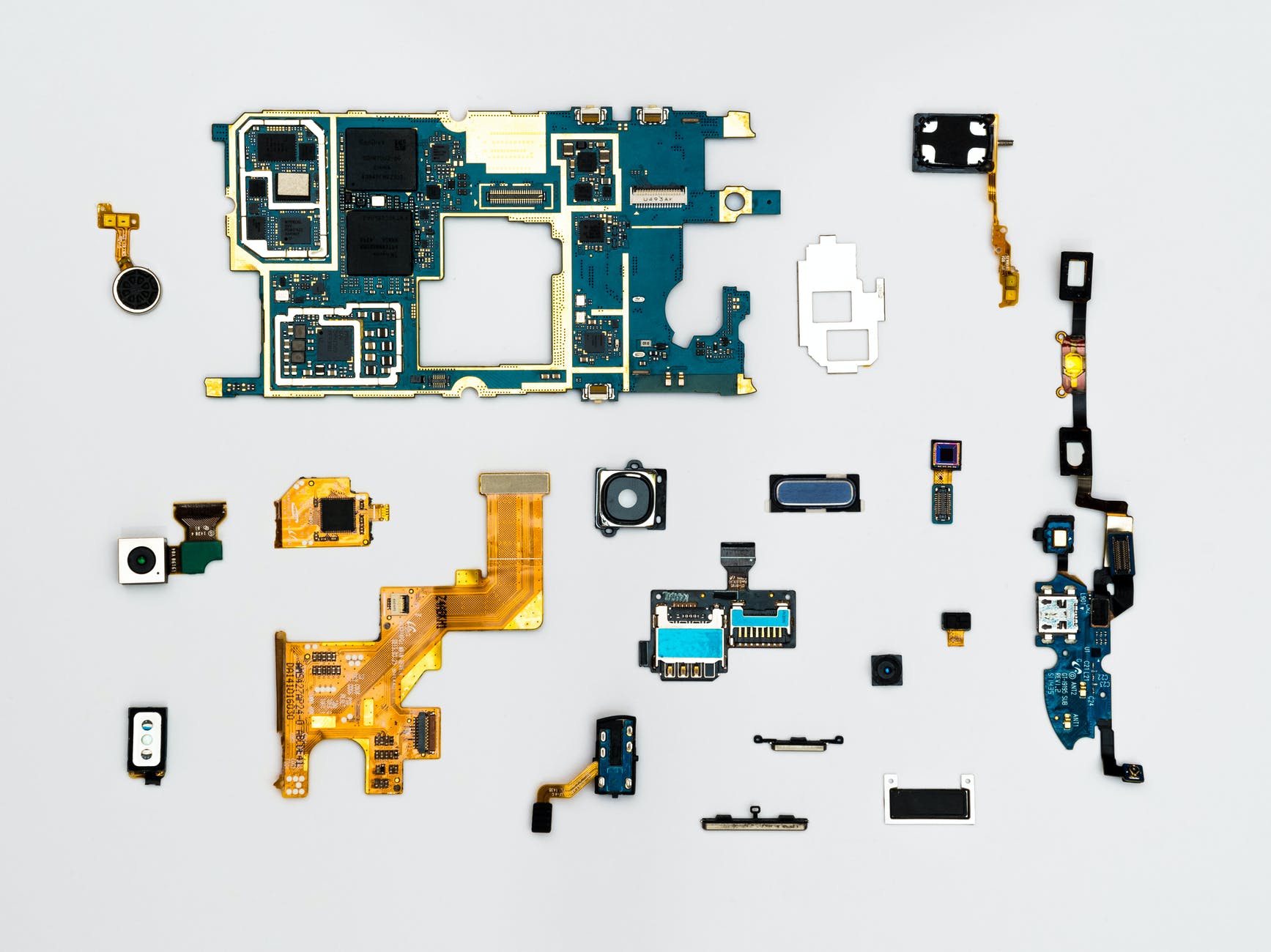

The FitMachine simply attaches to a piece of equipment via a magnet and uses a wireless sensor to collect data on vibration, acoustics, and temperature around the clock, in real time.

This data is processed and delivered by MachineCloud using machine learning and artificial intelligence. It is used to establish the equipment’s normal operating behaviour, monitor equipment degradation over time, and alert maintenance teams of abnormal behaviour. Machine failure can be predicted and prevented before it occurs, minimising unplanned downtime and production interruptions.

Let’s dive a little deeper into the four major ways that condition monitoring and predictive maintenance can offer serious value to operations and maintenance managers.

1. Prevent the Wasting of Resources

Let’s say that you have a machine that hasn’t been used in the past two weeks, but the schedule says it’s due for maintenance. It may or may not actually need the maintenance, but you don’t know because unfortunately machines can’t talk.

However, an equipment monitoring tool such as FitMachine can translate the behaviour of a machine in real-time, to tell you with greater certainty whether attention is actually require. This allows you to eliminate unnecessary maintenance, maximise the machine’s uptime, and free up your team to work on other tasks.

2. Avoid Sudden Breakdowns and Unplanned Downtime

Decreased productivity, missed production targets, and delays in product delivery are just a few of the major impacts that sudden breakdowns have on a plant.

By using predictive monitoring to catch abnormal equipment behaviour before it becomes a full-blown breakdown, you significantly reduce the chance of unplanned downtime and avoid the domino effect of inefficiency it causes.

3. Increase Efficiency and Overall Equipment Effectiveness (OEE)

In addition to preventing sudden breakdowns, predictive monitoring can also help you increase efficiency and overall equipment effectiveness.

The detailed data that the FitMachine provides gives you deep insight into your equipment. It allows you to see if assets are running as well as they could be. This provides huge opportunities for energy savings and can be a real boon to your bottom line. Not to mention the asset’s lifecycle.

4. Support Informed Decision-Making

We’ve said it before and we’ll say it again: good decisions require good data. After all, it’s garbage in, garbage out, to use a third cliche.

Having access to data about an asset’s history and how it performs is critical. Investing in this supports sound decision-making at all levels in the organisation. To make informed decisions, you obviously need to have information. Making that information easily accessible and digestible can give your organisation a competitive edge.

Foresight Is Better Than Hindsight

Equipment monitoring technology can have incredible benefits for operations and maintenance teams. Take the time to implement these simple solutions. Harness the power of data and artificial intelligence. It can save time, money, and resources. Plus, it’s smart, simple, and achievable.

The only question should be how soon you want to start seeing these results. Our recommendation? Start today so you can enjoy a better tomorrow.

Try MachineCloud for free – https://learn.movus.com.au/trial

Photo by Dan Cristian Pădureț on Unsplash