Continuous Condition Monitoring Case Study – Fertiliser Manufacturing

One of the key benefits of continuous condition monitoring is that it acts as an early warning system – giving maintenance teams advance notice of subtle changes that, if left unattended could degrade into more permanent damage or a failure. In late June, one of our chemical and fertiliser manufacturing customers provided feedback to us about an alert they received.

We were able to catch it before a critical failure thanks to FitMachine!

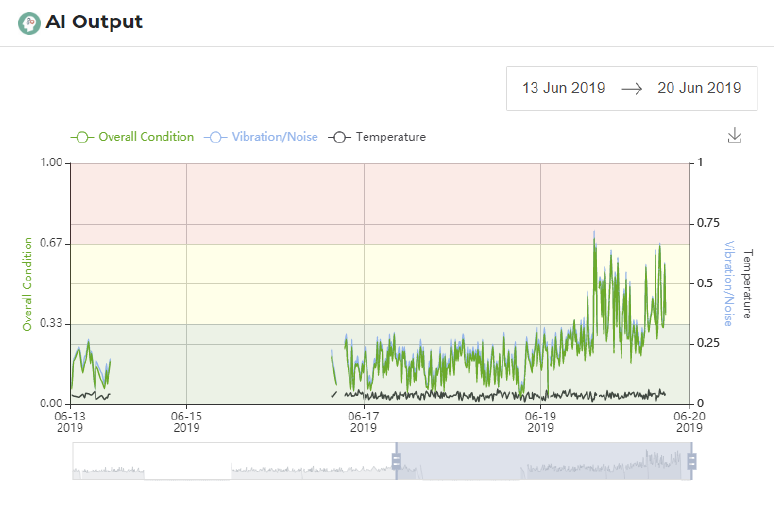

In this instance, FitMachine is monitoring a scrubbing plant fan. These fan units are critical assets as they ensure the removal and dust and fumes. As you can see in the screen shot below, FitMachine started detecting a change in condition and over a short period – check the grey trend line below the colour graph as the previous few weeks of data was showing very consistent, stabilised behaviour

We reached out to the customer to get some feedback as to the cause of the change. They noted:

“Because I received the text from movus, I called up the control room from my house, and was able to alert operations and they could adjust fan usage, and give it more grease until my maintenance team was able to change it out with the assistance of a crane. Our investigation found the non drive end bearing cage had collapsed”.

Worker Safety is Always the Number 1 Priority

The next piece of feedback is really important. We talk to customers a lot about worker safety, and this was validated by this customer:

This helped prevent downtime and potentially serious damage and injuries.

This is a great outcome for this customer and further demonstrates the value of our continuous condition monitoring solution. Feel free to contact us to learn more.