New Case Study – Matrix Polymers

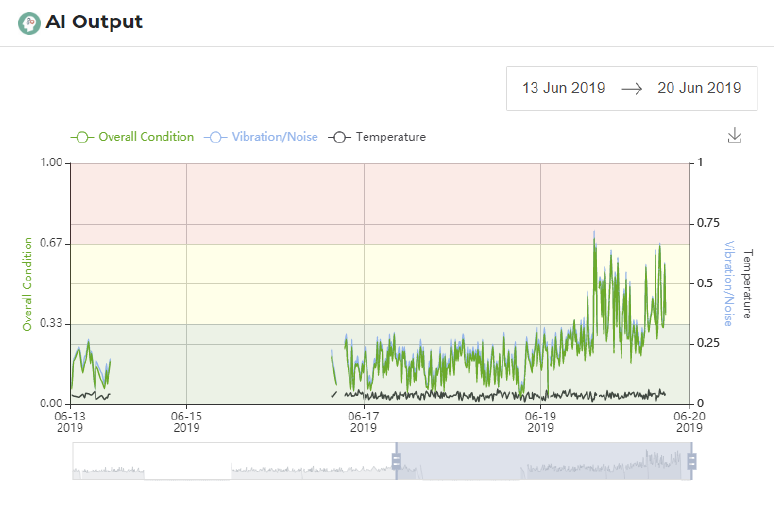

In manufacturing, unplanned downtime is a profit and reputation killer, and also significantly impacts a manufacturers ability to hit OEE targets (as MOVUS discussed with OEE expert Clive Moore earlier this year). This new case study from Australian manufacturer Matrix Polymers highlights the value of continuous condition monitoring.