Our March Update: New Notifications, Editable Max RPM & More!

Hello and good morning! It's lovely to have you here again.

Thank you to those who checked out our feedback form in the last update. In case you didn't get a chance to share your thoughts, I thought I'd give you the opportunity again here. Merci!

PRODUCT

Everything you need to know, in the one place.

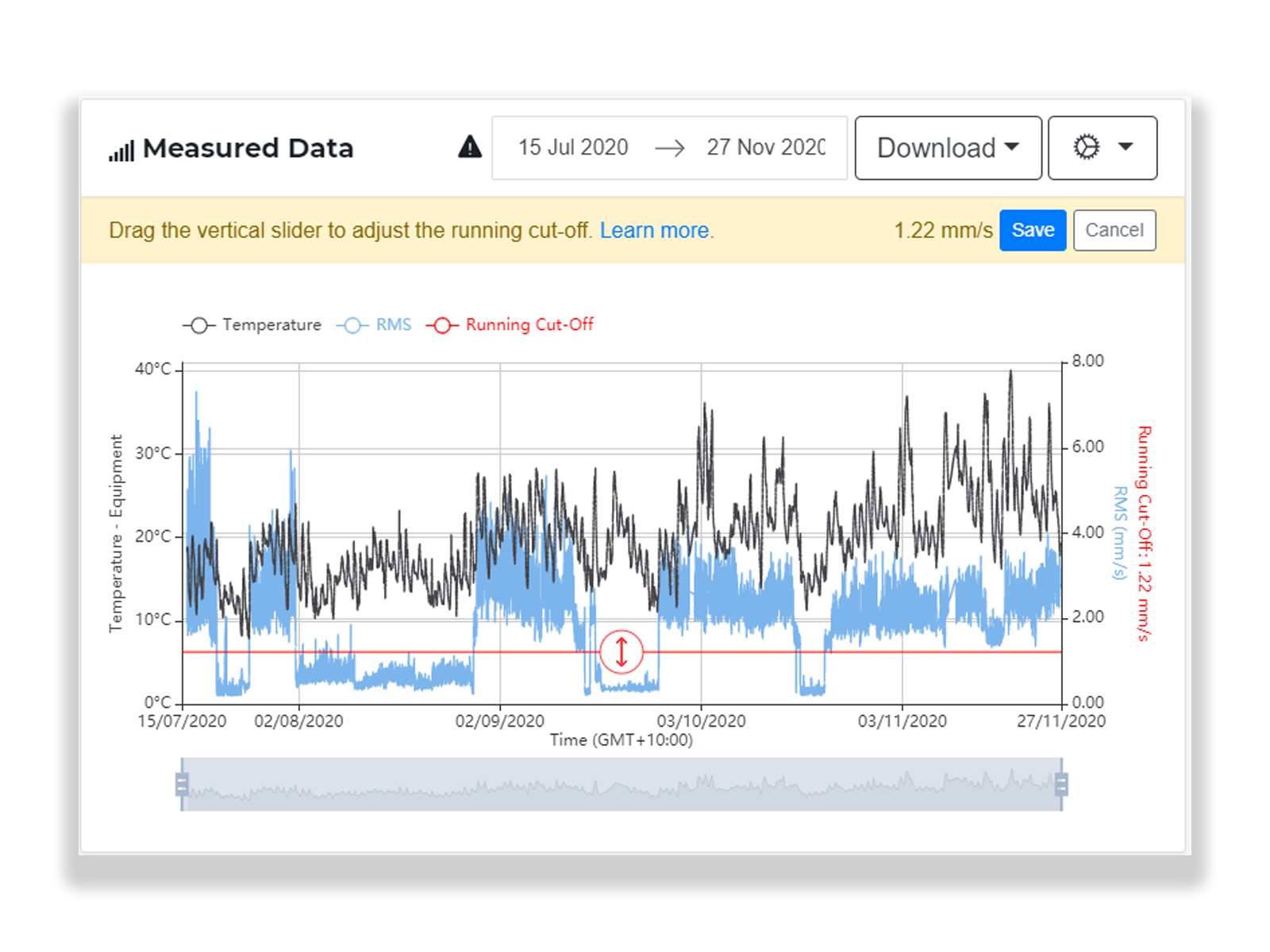

To help you stay informed of the latest events and issues across your equipment, we've expanded our notification system.

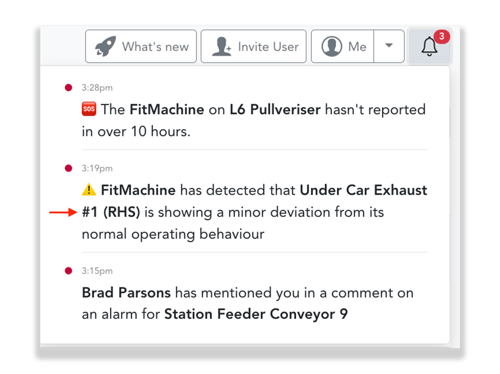

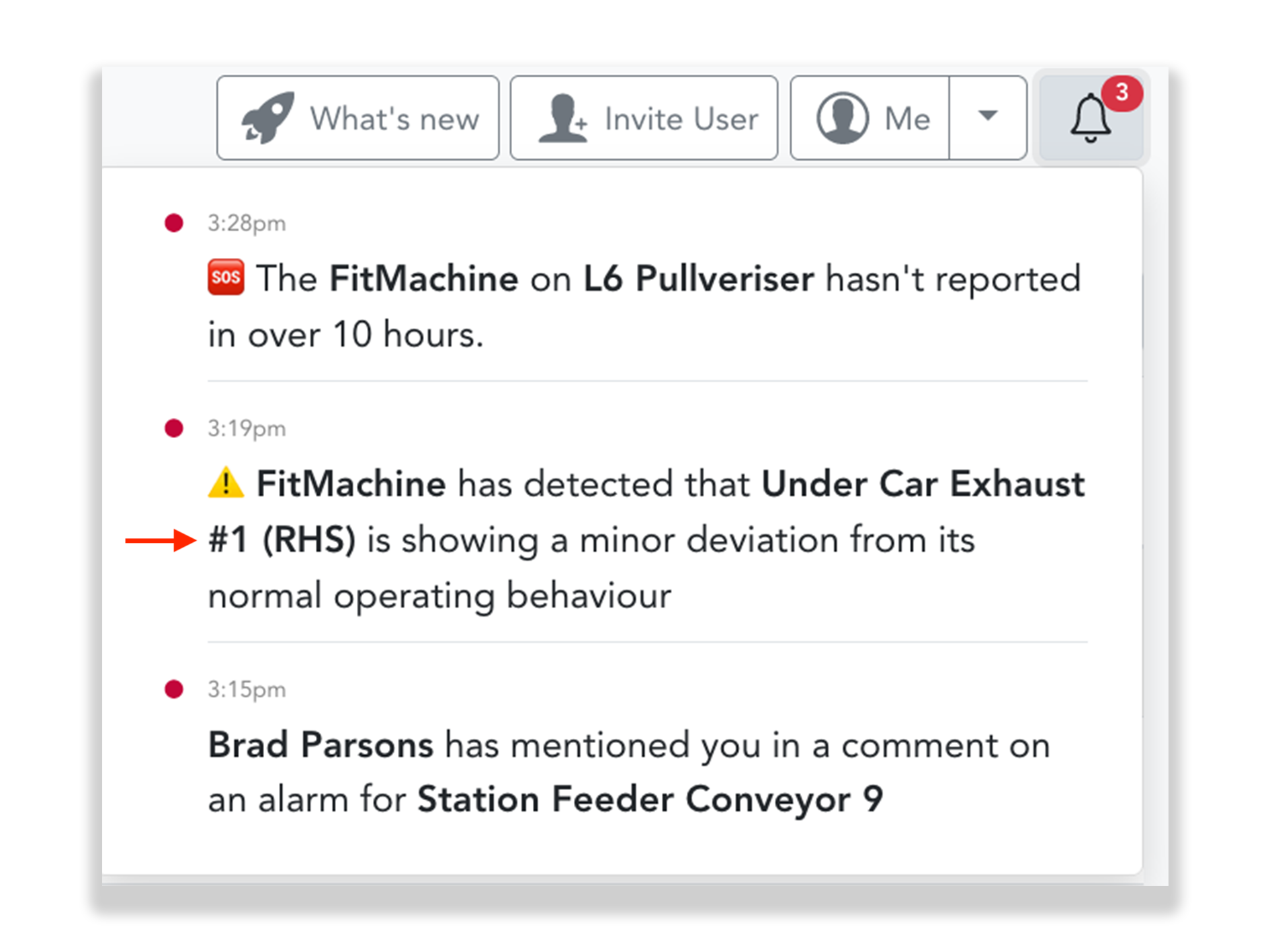

Now, alongside notifications about Mentions, you will receive notifications within the dashboard about new alarms. Both yellow advisories and red alerts, advising you of changes in your equipment's condition, are now consolidated into your Notification Centre, providing an easy way to review alarms.

PRODUCT

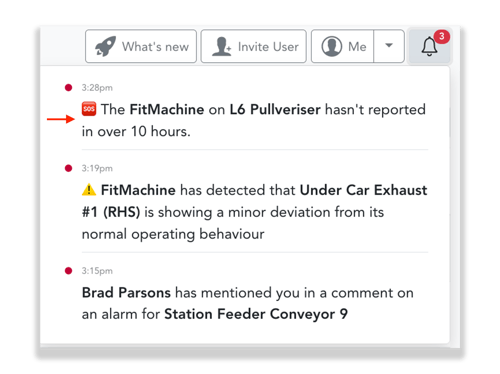

Non-Reporting FitMachine Notifications

But wait, there's more! Notification Centre has also been updated to include notifications about non-reporting FitMachines. That means you'll also be aware anytime a FitMachine loses communication with your dashboard so you can investigate for network, battery or hardware issues.

PRODUCT

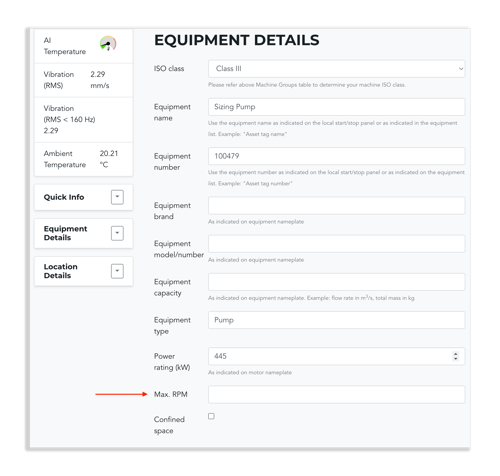

Editing Max RPM is now possible!

Now, picture this: you've run out of time to input your equipment's details during onboarding, and decide to flesh out the details later, back at your desk. But, when the time comes, you find you can't edit the equipment's Max RPM. How frustrating.

Not anymore! Originally, you couldn't edit the Max RPM if it wasn't input during onboarding. However, you can now edit this field like any other on your equipment's detail page.

FEATURE CUSTOMER

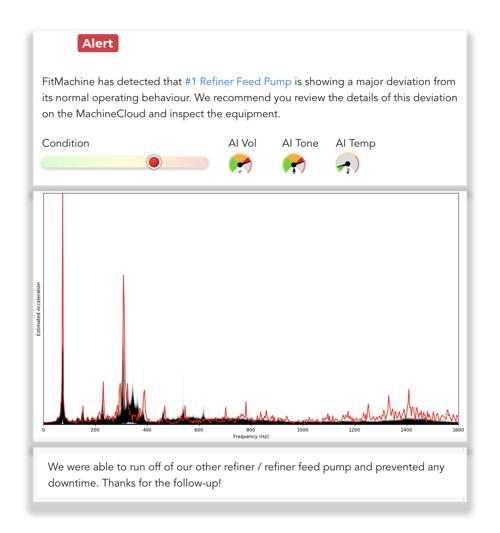

How this heavy manufacturing plant saved production downtime!

Finally, we thought we'd share a great example of FitMachine in action. Recently, maintenance teams at a customer's heavy manufacturing plants were alerted, late in the evening, to a major deviation in behaviour for a refiner feed pump. It was identified that belts had been burnt, needing replacement before a complete failure occurred.

Thanks to the heads up from FitMachine and the ability to tag team members on the dashboard, the overnight shift team could switch over to another feed pump while belts were replaced on the original asset.

Production downtime was avoided and required repair completed within the same shift! This just goes to show how much time, money and resources you can save with 24/7 equipment monitoring.

In case you missed it...

BONUS: Some of our latest updates you may have missed:

---

That's all for now! Enjoy the rest of your day.

Cheers,

Hayley and the MOVUS Team.