FitMachine Reduces VA Inspection Frequency & Prevents Equipment Failures

Cover image sourced from: https://www.longbeachconcreteservice.com/

Recently, one of our mining customers shared how FitMachine has made a difference in their organisation. It's a fantastic asset fitness insight we had to share.

They are located in a fairly remote site and have had FitMachine for several years now. The sensors are embedded into their day-to-day practices, and the teams monitor the FitMachine Dash from their control room. This integration has enabled them to establish processes with 24/7 oversight AND save time and money, the two most valuable resources.

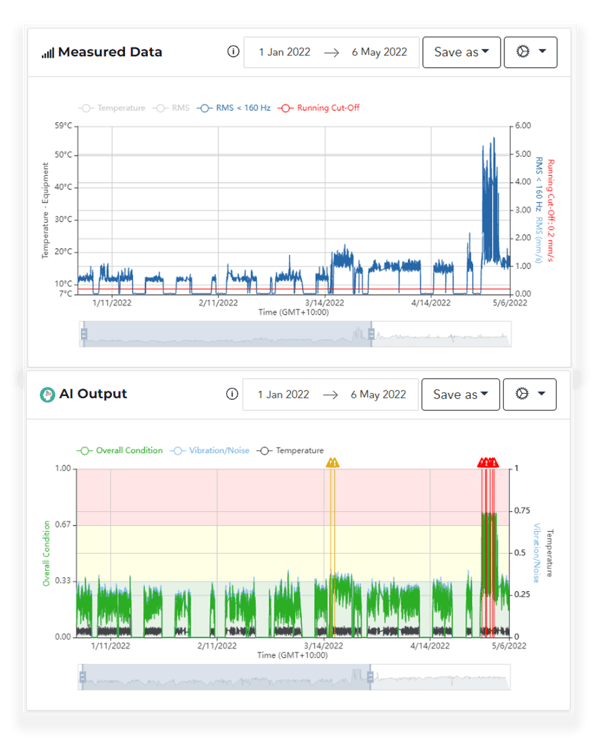

The company champion, a Reliability Engineer at one of the sites, was excited to show just how. He demonstrated that there have been a number of instances where FitMachine has detected valid issues overnight and alerted the team. You can see an example of the pickup in the attached image direct from their dashboard. This early insight has enabled them to take timely action and save time and money on several occasions by avoiding unplanned downtime.

What's more, visibility over their assets has given them the confidence to reduce the regularity of inspection by Vibration Analysts and total inspections overall. By relying on the visibility and data that FitMachine provides, the mining sites have been able to better determine what maintenance needs to be performed, ahead of time. Now, with sufficient time to complete maintenance, they've reduced both the costs of routine inspections, unnecessary maintenance and unplanned downtime.